Iqc

IQC is the department responsible for inspecting raw materials, ensuring that the products used online are of good quality through the inspection of incoming materials, thereby ensuring production quality. IQC also has the function of managing supplier quality. The full name of IQC is Incoming Quality Control, which means incoming quality control. At present, the focus of IQC is not only on the quality inspection of incoming materials, but also on controlling the quality of incoming materials.

The following are the scope and requirements of IQC's work:

1、 Inspection specifications

Inspection specifications define the product acceptance specifications in the form of documents as the fundamental basis for inspector inspection, with specific forms such as documents and images, limit samples, and so on. This specification tells the inspector what is acceptable and must be clearly defined and executable. Inspection specifications are formulated by referring to industry standards and combining them with customer standards. Inspection specifications are dynamic documents. If there are any additions or changes to the specifications, salespeople, tracking and procurement personnel must promptly convey them to the inspectors and make changes to the inspection specifications as soon as possible.

2、 Sampling plan

The sampling plan shall refer to industry standards and customer requirements. The sampling quantity should be determined based on the quality status of the supplier to select more or less samples. It should be noted that for special packaging or destructive inspections, it can be determined based on the specific situation. If the quality status of the supplier is poor and needs to be monitored, it is necessary to arrange for more sampling. Similarly, for suppliers with good quality performance, exemption from inspection should be considered for suppliers or part numbers, and conditions for exemption should be established. After approval by the quality manager, exemption from inspection can be implemented. The ultimate goal is to block defects without wasting manpower.

3、 Sampling techniques

Random sampling, Stratified sampling and systematic sampling, etc. In order to prevent defective leakage, Stratified sampling is applied in principle, which needs to be supervised by the supervisor.

4、 Preparation of inspection equipment and materials

The inspector needs appropriate equipment for inspection. The equipment needs to be accepted, Measurement system analysis and regularly calibrated. The inspection data refers to the drawings, specifications

Samples, limit samples, etc., must be provided to IQC by all engineering units before arrival and uploaded to the company's cloud disk.

5、 Handling of incoming material anomalies

After completing the inspection of all items, the IQC inspector shall write down all abnormal items and defect rates on the abnormality list and send an email to the procurement, PMC, supplier and other units. Each relevant unit shall hold an MRB meeting to decide on special procurement, return, selection, scrapping and other handling methods. After the decision is made, the warehouse, IQC, and supplier shall be notified of the handling methods, and a quality abnormality contact letter shall be sent to the supplier, requesting a response and a deadline for recovery.

6、 Organization of inspection data

IQC is responsible for organizing and analyzing supplier quality abnormality reports, facilitating supervisors to timely understand the quality status of suppliers, and serving as a basis for supplier performance evaluation and selection of eliminated suppliers.

7、 Supplier Management

For supplier quality abnormalities, it is necessary to submit an 8D report, and it is not necessary to open 8D every time. The supervisor can determine whether to open 8D based on the degree of risk. For suppliers who respond to 8D reports, they need to be qualified in a timely manner and track the actual improvement effect.

Regularly conduct on-site audits of suppliers to confirm their quality management status. Based on product characteristics, on-site audits such as warehouse, inspection, on-site management, abnormal improvement, and document management can be conducted. For anomalies with high quality risks found, rectification orders need to be issued and a deadline for rectification is required.

8、 Quality Agreement

When entering into a quality agreement, the quality requirements are determined in the form of an agreement with the supplier, including batch return rate, online defect rate, and major abnormal fines, which can serve as the basis for fines.

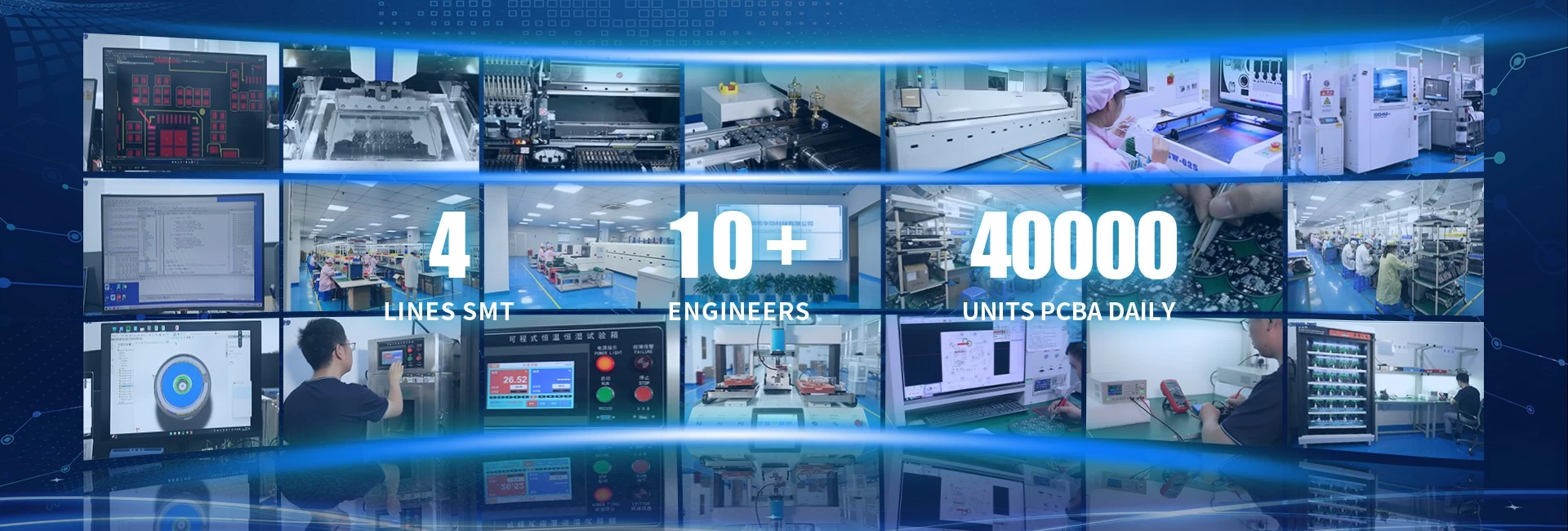

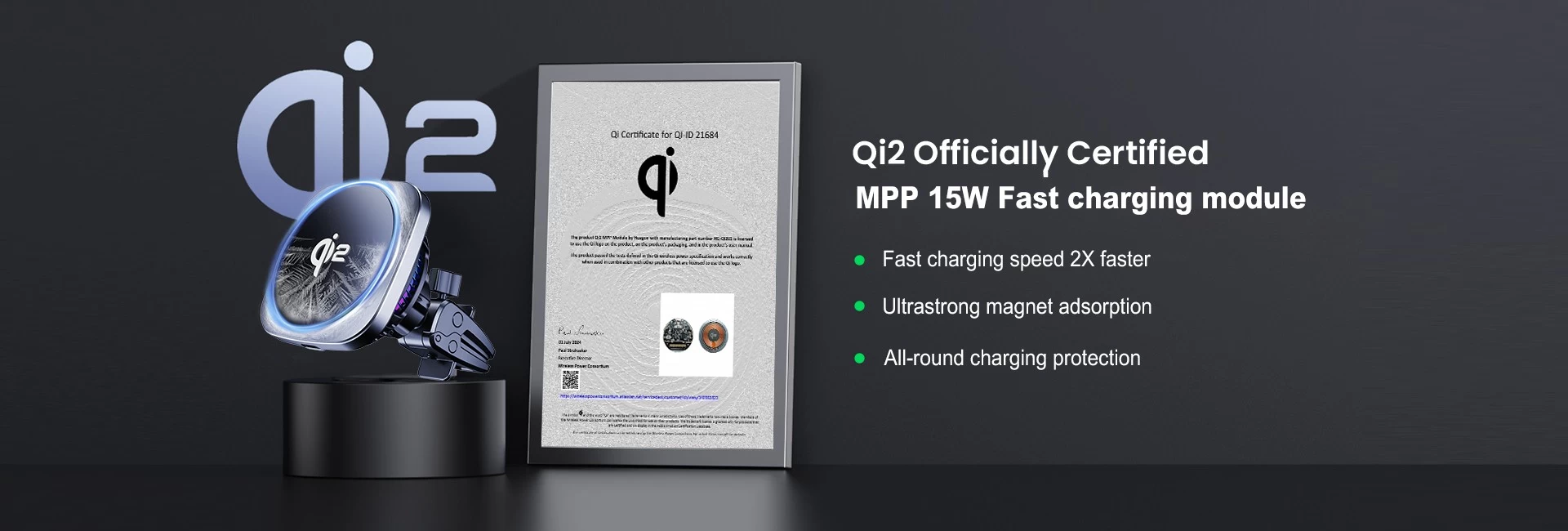

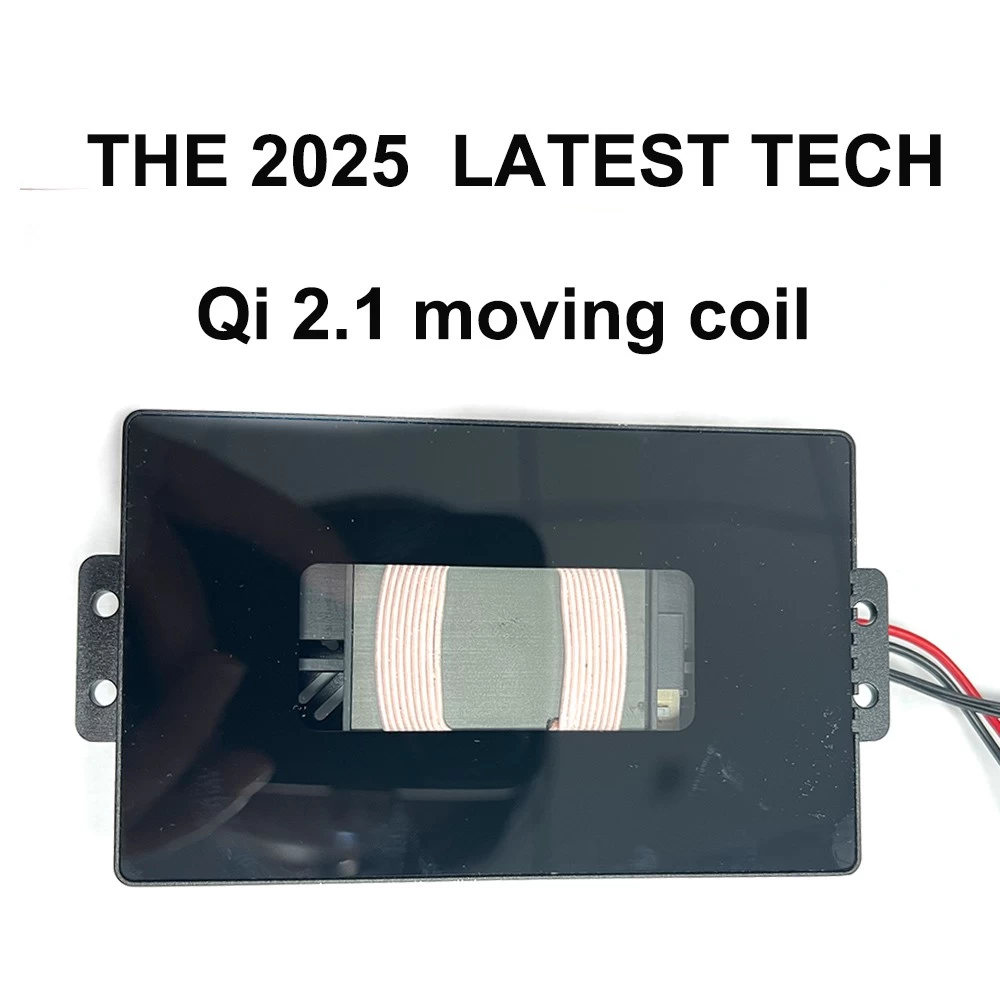

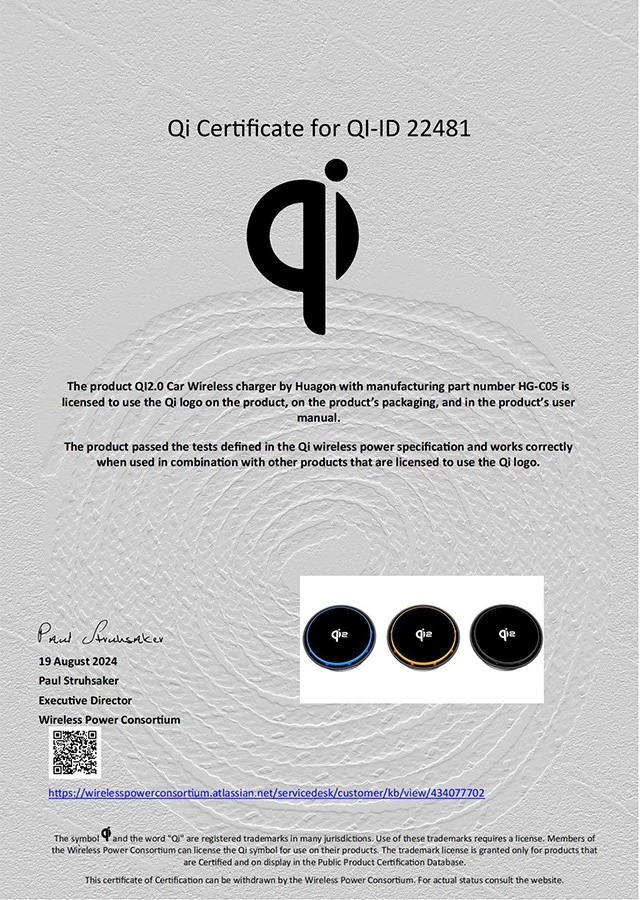

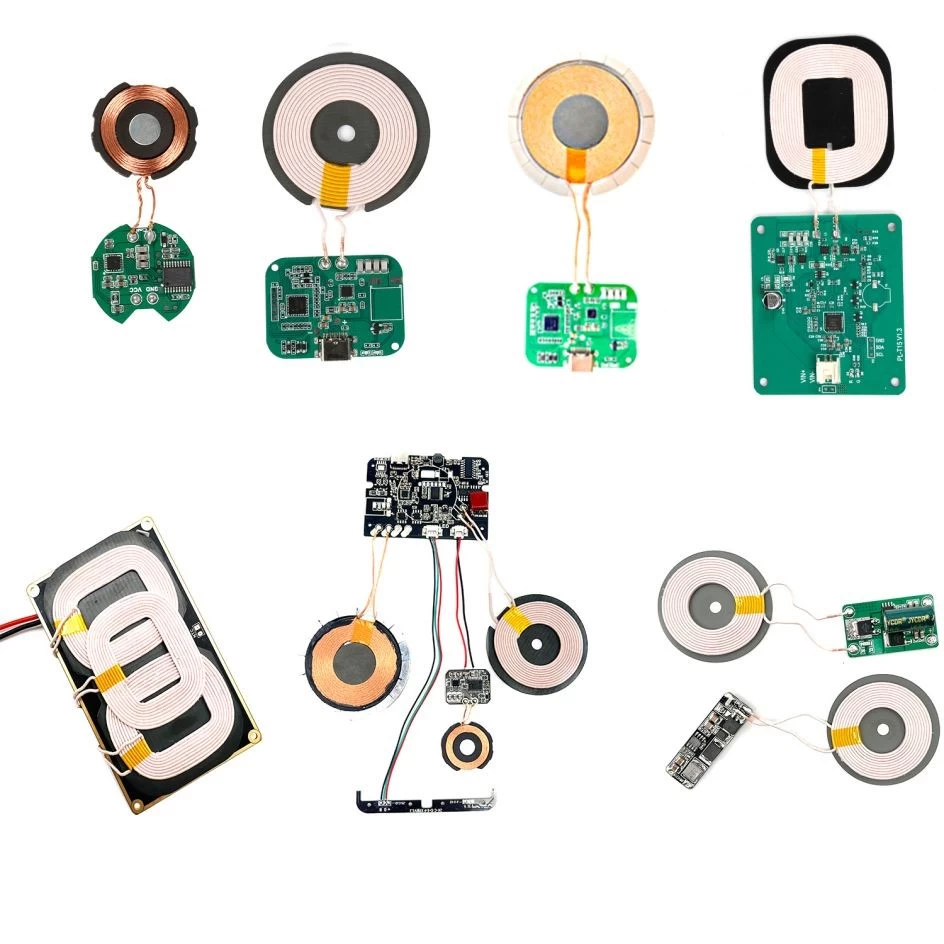

Shenzhen Huagon technology majors in wireless charging customization for more than 10 years, we are professional China wireless chargers suppliers and China wireless chargers manufactures. As China shenzhen wireless chargers wholesalers, we have designing team, SMT factory, and production factory, which makes us prominent wireless chargers manufactures.

The power of quality cannot be underestimated, as it has the power to return and impose fines, and can organize quality reports for the boss to see. If suppliers are not aware of this, they can use returns and fines to remind them. If there is no improvement, it can be upgraded. You can compile the return records and evidence of repeated defects into a report for the boss to see, and use data and images to refute rumors.

9、 Future work direction

The work direction of IQC should shift from passive inspection to active control, moving quality control forward, identifying quality issues at the forefront, reducing quality costs, achieving effective control, and assisting suppliers in improving their internal quality control level