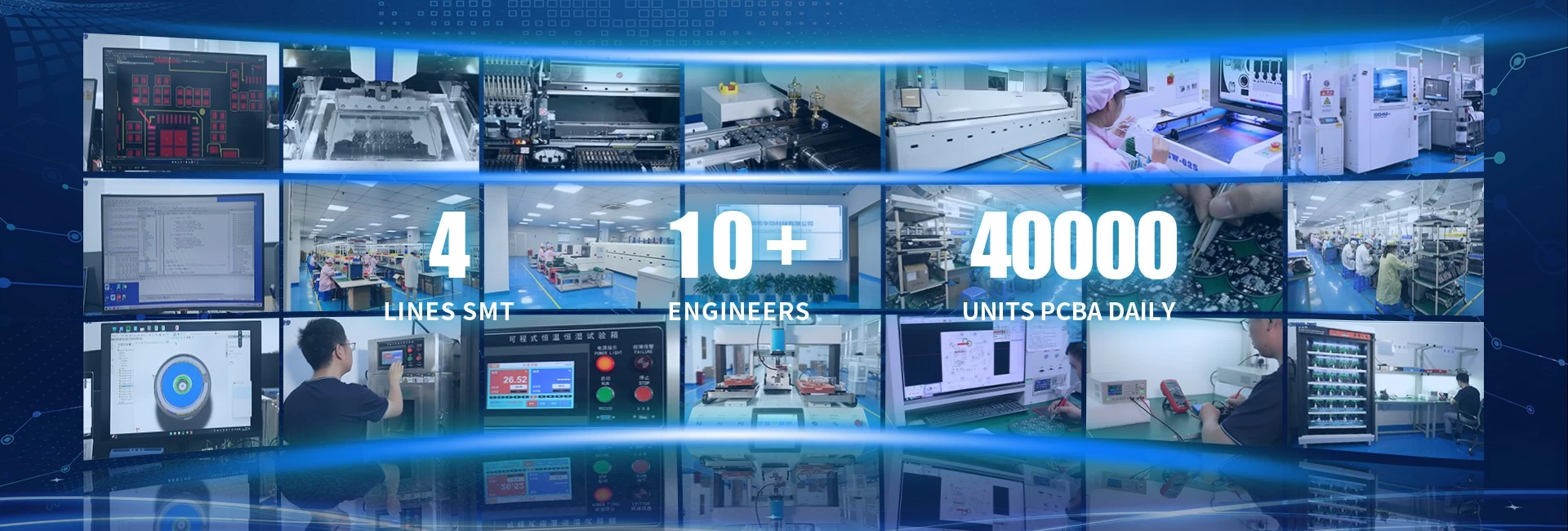

The assembly workshop is also a standard dust-free workshop with 6 production lines and over 60 skilled assembly workers.: According to the requirements of ISO9001 documents, we have a strict quality inspection process. IQC, IPQC, FQC and OQC assure that everything is strictly examined and perfect in quality.

IQC: SOP and work instructions for incoming materials, inspecting the appearance, size, and functional defects of electronic materials and plastic parts. If the raw materials are not qualified, they will be quarantined, returned to the supplier, and a quality abnormality contact form will be issued. The supplier will provide preventive measures.

IPQC: Once production begins, there will be inspectors patrolling the production line at all times. If unqualified products are found during the inspection, the production line will be stopped if there is an excess, and preventive and corrective measures will be identified. If there is no excess, the cause will be analyzed. If there are any abnormalities, issue a quality abnormality contact form, urging analysis of the reasons and finding response strategies.

FQC: After the product is installed, it is actually applied to intelligent devices and tested for product performance using a professional tester. At the same time, conduct visual inspection.

OQC: The final step of the production line is to conduct a full inspection before entering the warehouse. After entering the warehouse and before shipping, spot checks should be conducted based on the sampling level before shipping.