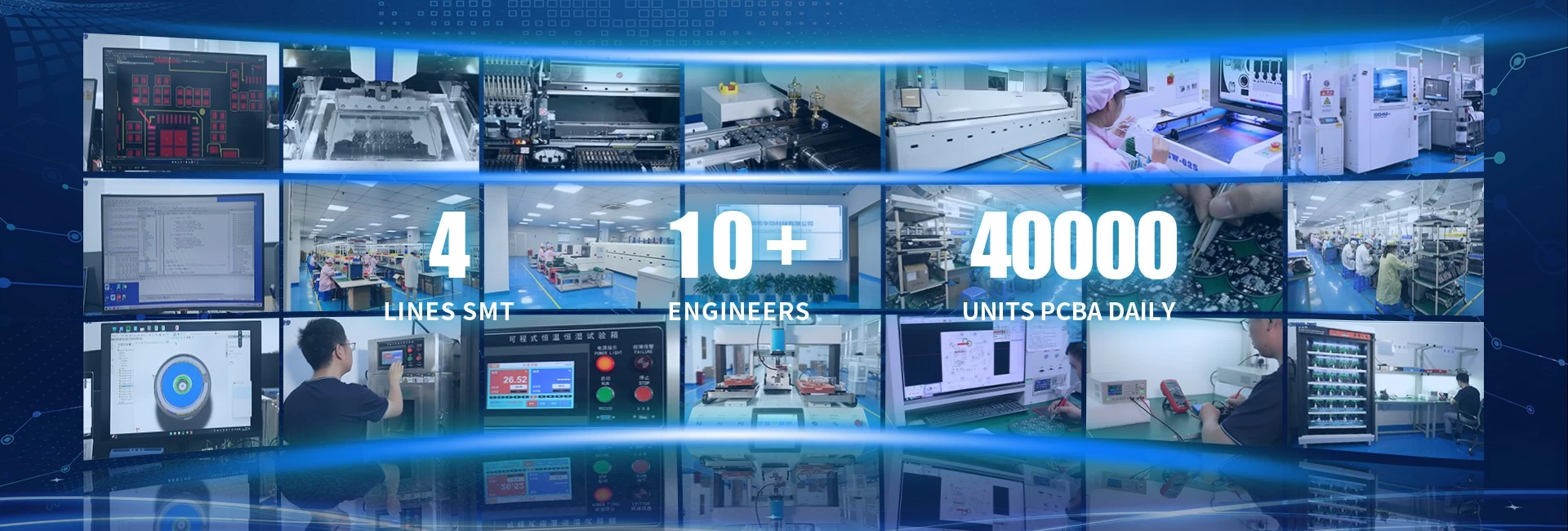

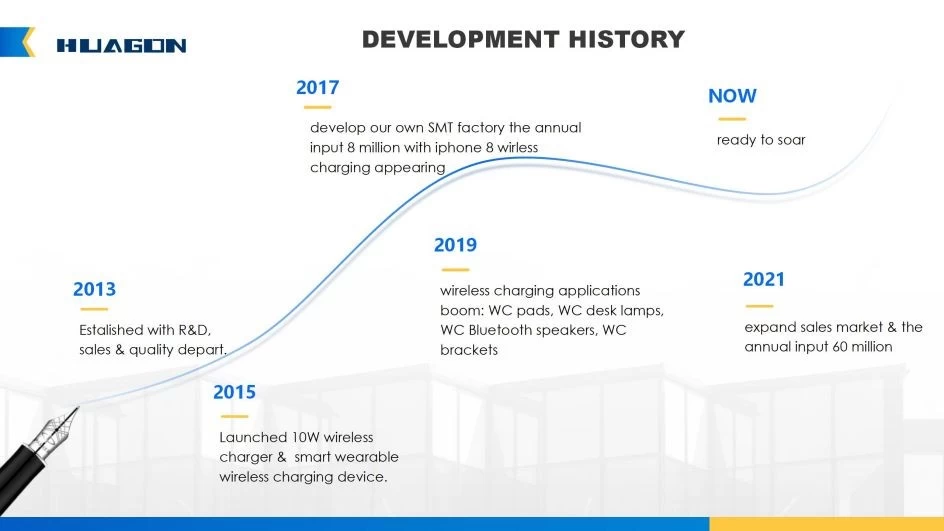

Shenzhen Huagon Technology Co., Ltd. focuses on wireless charging customization and mainly engaged in the R & D and production of wireless charging PCBA, wireless charger, vehicle mounted wireless charger, furniture wireless charger, wireless transmitter & receiver and mobile power supply.. The core team members of Huagon Technology's chip development are all senior professionals in the field of chip design, many of whom have 10 to 20 years of rich design experience in the chip industry.

The design team of our company is divided into six software engineers, six hardware engineers, four structural engineers, one board sticking personnel and one maintenance personnel.

The design team of our company is divided into six software engineers, six hardware engineers, four structural engineers, one board sticking personnel and one maintenance personnel.

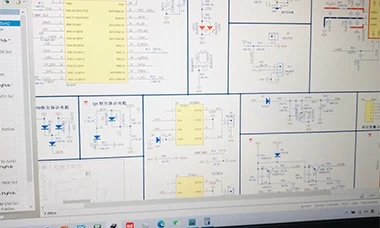

Among them, hardware engineers excel in:

1. New product schematic drawing, PCB drawing, sorting and developing BOM, device selection, prototype production and commissioning, Software design description archiving, production import, etc;

2. Based on the requirements document, responsible for conducting project research on hardware solutions, writing hardware design solutions, and outputting BOMs;

3. Import PCB design files for product schematic design, guide PCB design, review detailed model selection and review of components in the product BOM, and develop and maintain the supply chain;

4. Responsible for the hardware research and development of high-power DC/DC converters, mainly including schematic design PCB design, BOM compilation and organization, component selection, prototype production and debugging, prototype reliability testing, EMC testing, and product production import;

5. Circuit scheme design, circuit simulation, PCB layout design, EMC testing, and related document preparation work;

6. Circuit diagram optimization design, PCB layout design, sampling, and software department cooperation to debug the program, prototype welding debugging, component purchase and selection, SMT steel mesh and other production process documents output;

Software engineers excel in:

1. The algorithm development of Big data real-time filtering system supports the writing of complex filter condition expressions (such as time filter, threshold filter, binary expression filter, etc.), and realizes the writing of GIS regional filter algorithms, optimization of some algorithms, and testing of various algorithms;

2. Participate in usability optimization, reorganize and categorize project file paths, simplify file structure, enable users to quickly extract the required data files, and improve software usability;

3. MOS algorithm testing and optimization, by classifying and intercepting different input audio packets, reassembling them into audio, and then calling different algorithms based on user selection to perform MOS scoring on the intercepted audio; Test and optimize the MOS speech estimation algorithm, including testing and analyzing audio, testing intercepted audio, adjusting thresholds and audio start and end times to optimize the audio interception algorithm.

4. File structure optimization, removing useless block indexes, adjusting the code for writing and reading files, and testing the optimized files in various environments.

Structural engineers are good at

1. Feasibility analysis, design, and problem localization and resolution of product mechanical solutions;

2. Product structural design, assembly testing and validation of new products;

3. Mold opening evaluation, improvement, and structural cost control;

4. Lead small batch trial production and trial production review meetings for new products;

5. Preparation and output of technical documents such as product BOM, relevant drawings, product technical standards, and product user manuals;

6. Improve the structure and process design problems in the Product lifecycle;

7. Research and explore new processes and technologies that can be well applied to company products.

We are ready to serve you.