Huagon – Global Leader in Custom Wireless Charging Solutions

Huagon – Global Leader in Custom Wireless Charging Solutions

Since its establishment in 2013,Huagon has been dedicated to in-depth R&D and high-end customization of wireless charging technology. With 10 years of industry expertise, vertically integrated supply chain capabilities, and military-grade quality standards, we have become the strategic partner of choice for 500+ global brands.

click China Wireless charging manufacturer to know more.

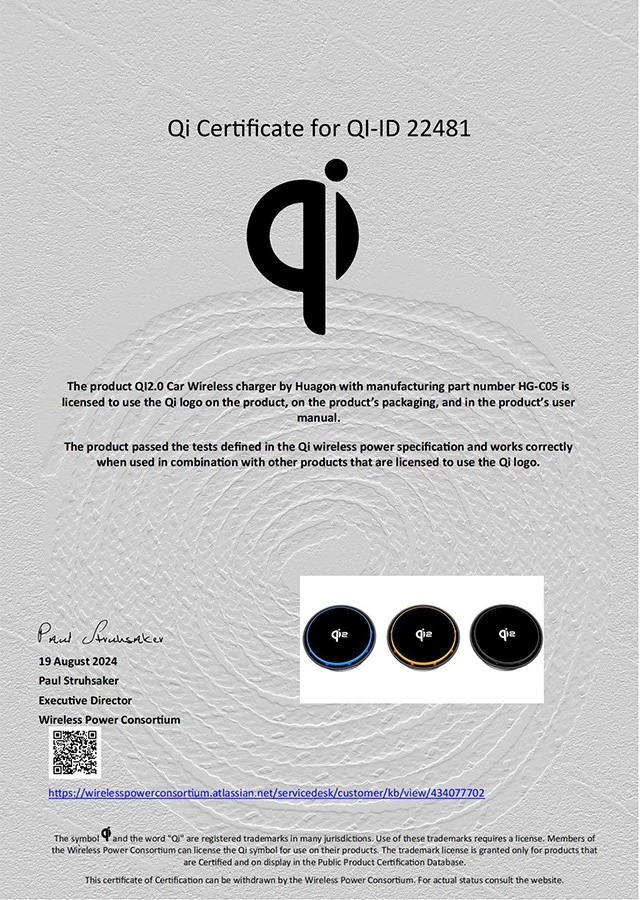

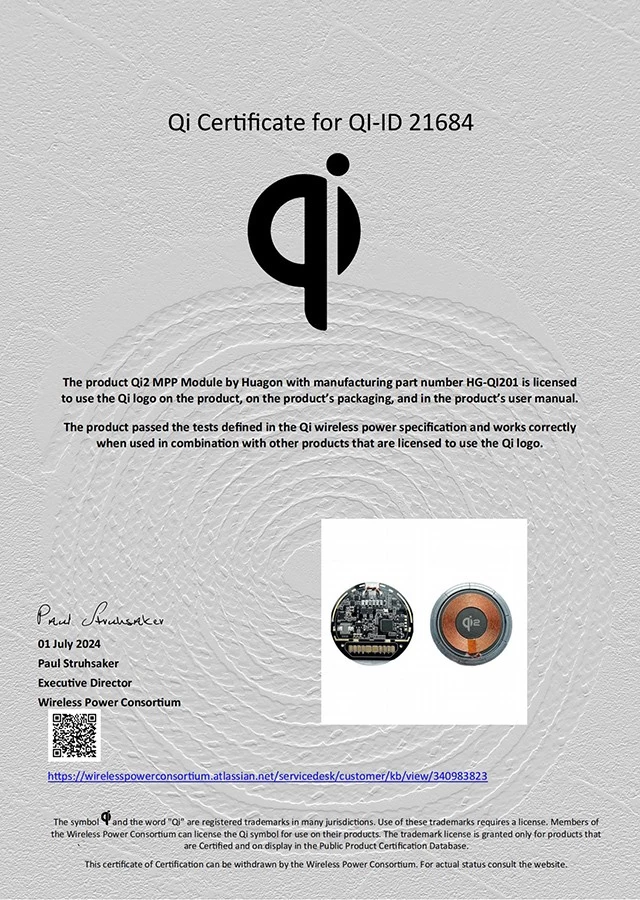

As a core member of the Wireless Power Consortium (WPC) and certified under ISO 9001 and IATF 16949 quality management systems, we specialize in the industrial application of high-frequency magnetic resonance coupling technology and electromagnetic field optimization algorithms, holding significant technical advantages in the 15W-100W mid-to-high power wireless charging segment.

We are not just a supplier but a technology co-creator, offering full lifecycle services from **concept design → R&D validation → mass production → after-sales support**, empowering clients in smart wearables, consumer electronics, smart home, automotive electronics, and medical devices to build differentiated competitiveness.

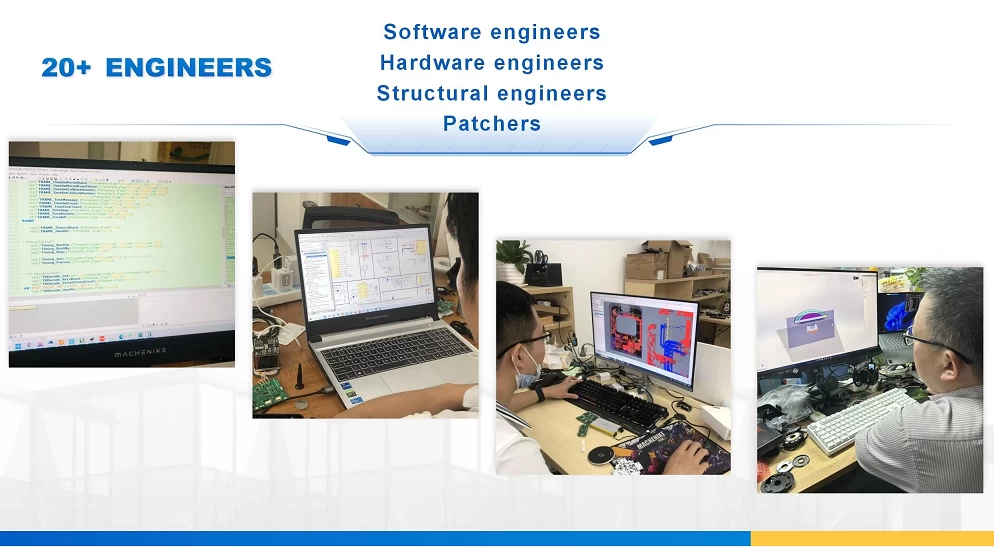

I. R&D: 20+ Engineers Driving Core Competitiveness

1. Hardware Design – Perfect Balance of Efficiency and Stability

- High-Efficiency Architecture: Third-generation GaN + MCU dual-chip architecture achieves over 85% charging efficiency (industry average: 78%) with 30% better thermal performance than Qi standards.

- Anti-Interference Expertise: Proprietary "sandwich" shielding structure effectively suppresses EMI radiation, passing automotive-grade CISPR 25 Class 5 tests.

- Multi-Scenario Adaptability: Supports 5W-100W full power range customization, compatible with smartphones, earbuds, drone batteries, and other specialized devices.

2. Software Systems – Protocol Compatibility & Smart Interaction

- Full Protocol Support: Beyond Qi 1.3/BPP/EPP/MPP, supports private customization of A4WP and AirFuel protocols, with embedded encryption chips for device authentication.

- AI Dynamic Tuning: Real-time foreign object detection (FOD) and receiver positioning, with automatic power adjustment (FOD false trigger rate < 0.001%).

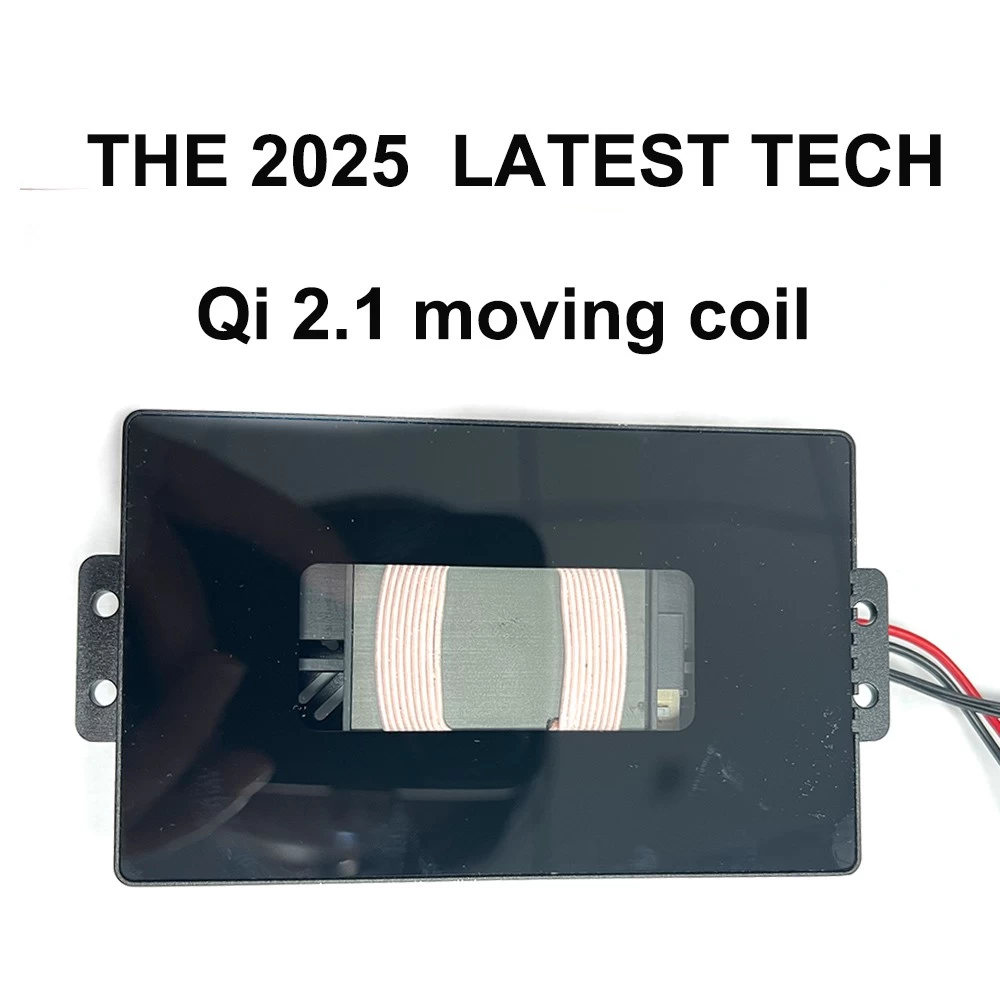

3. Structural Innovation – Fusion of Aesthetics and Functionality

- Ultra-Thin Design: As thin as 2.8mm (including coil), using nano-level IML technology for curved glass integration.

- Special Environment Adaptation: Military-grade rugged design (IP68 waterproof/dustproof/shockproof), stable operation from -40℃ to 85℃.

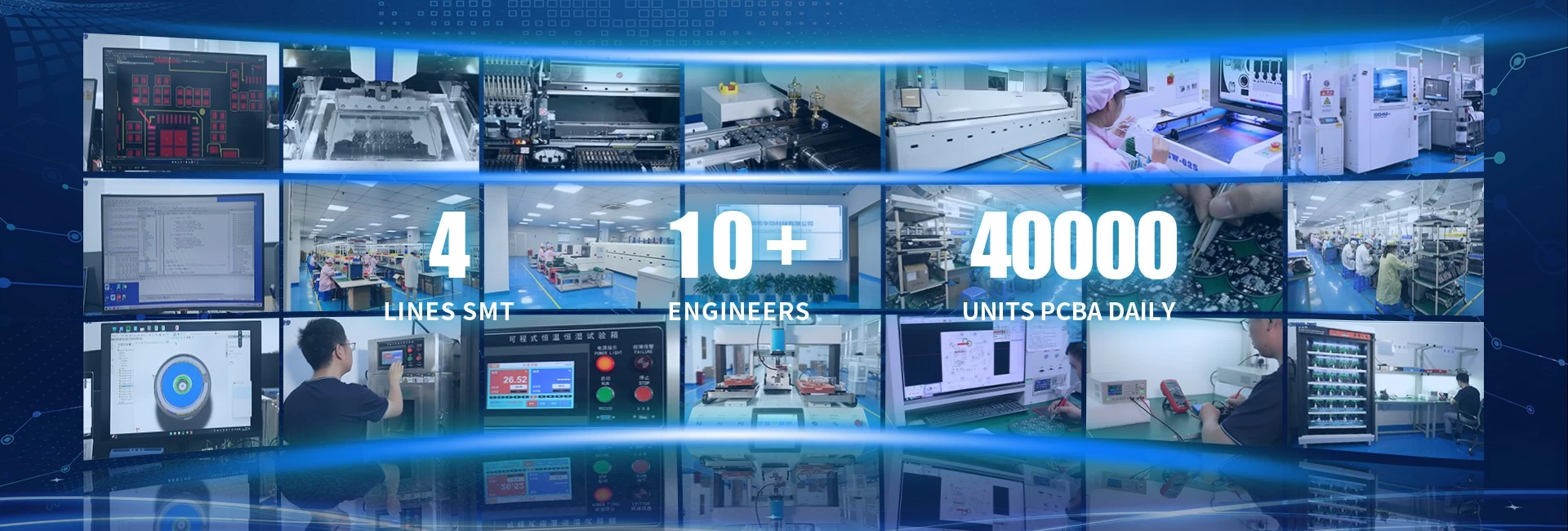

II. Manufacturing: Full-Process Control with Zero Quality Compromise

1. SMT Cleanroom – Precision and Scale Combined

- Fully Automated Production Lines: Equipped with Japan’s Fuji NXT III placement machines (±25μm accuracy) and 3D SPI inspection systems, daily capacity reaches 500,000 points.

- Dual Quality Checkpoints: AOI optical inspection + manual recheck, PCBA first-pass yield ≥ 99.97%.

2. Molding & Injection – Pursuit of 0.005mm Precision

- Precision Mold Partnerships: Jointly developed with Shenzhen’s top 3 mold factories, cavity accuracy reaches mirror-grade (Ra ≤ 0.05μm), lifespan exceeds 1 million cycles.

- Specialty Material Applications: LDS laser direct structuring, PPS high-temperature plastics, meeting automotive/medical requirements.

3. Assembly & Testing – 3 Extra Inspection Steps vs. Industry Standards

- Full Inspection:

- First-article inspection (100% parameter testing)

- Aging test (72-hour full-load cycle)

- Final full inspection (including drop/salt spray and 20+ reliability tests)

- Sampling Standard: AQL 0.65 (industry standard: AQL 1.0), batch defect rate ≤ 50 PPM.

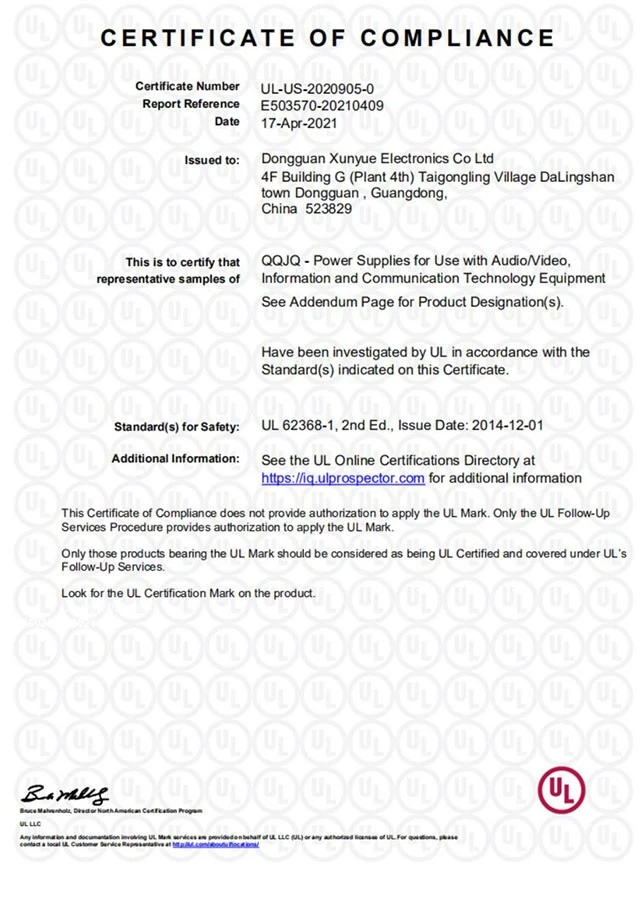

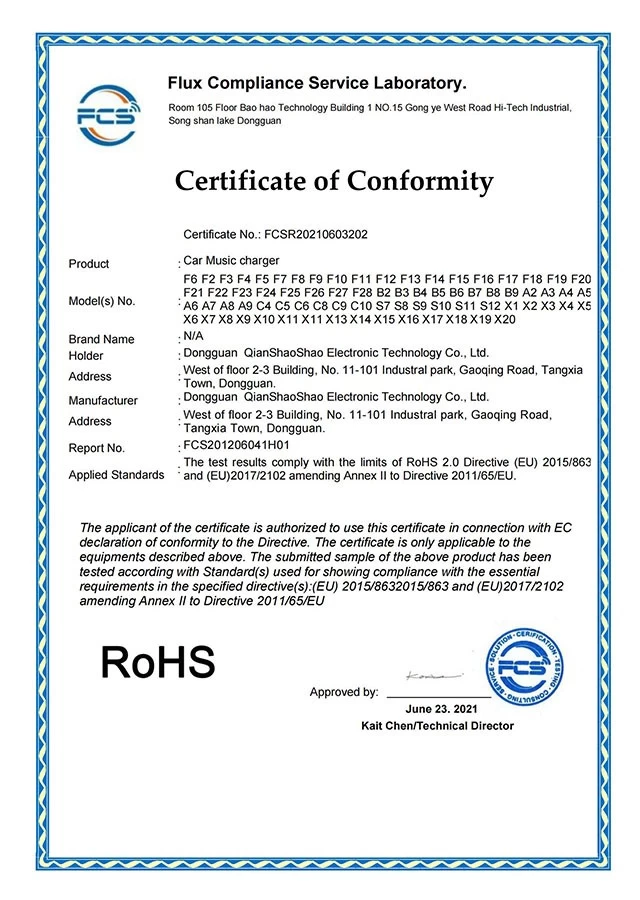

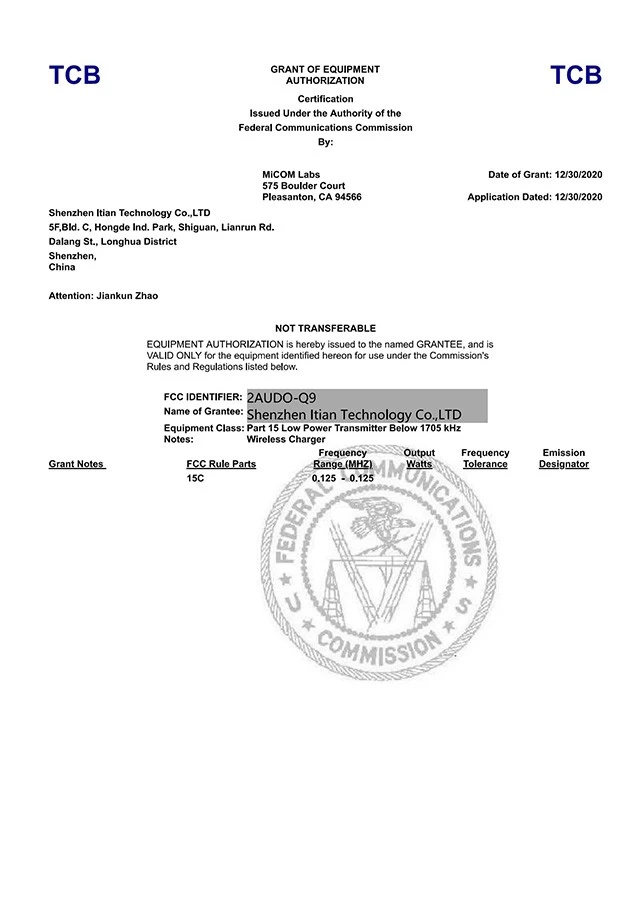

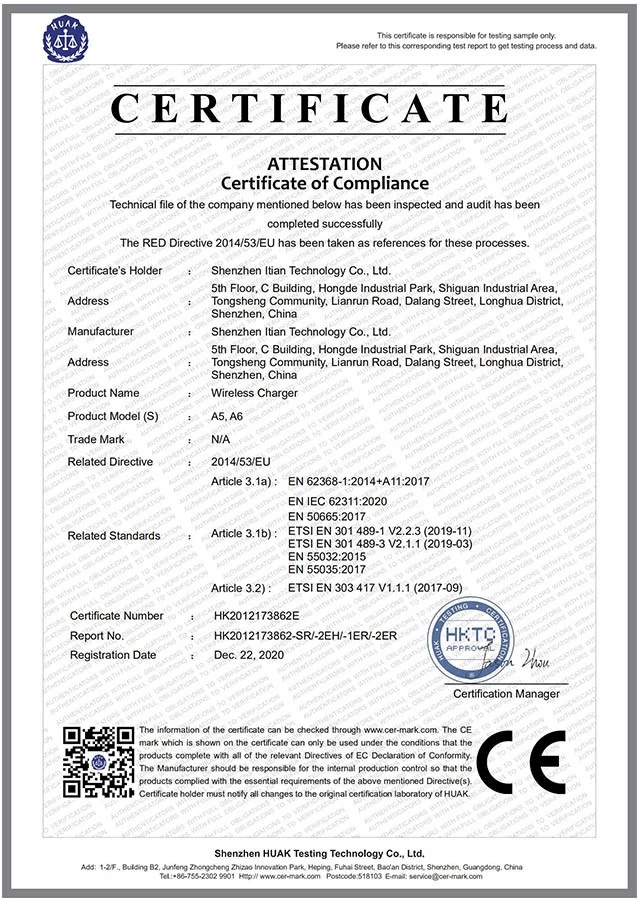

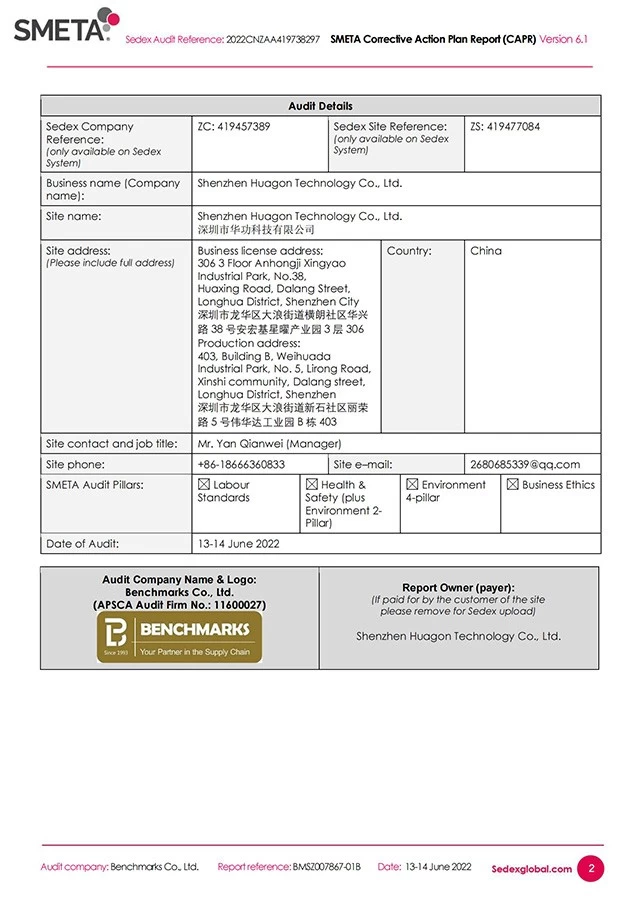

III. Certifications & Compliance: Fast-Track to Global Market Access

1. Authorized Partnership Network

- Domestic: Collaborative "pre-test lab" with MICRO TEST reduces certification cycle to 12 working days (industry average: 30 days).

- Internationa*: Witnessed testing by TÜV Rheinland, UL, FCC, with a 92% first-pass rate.

2. Representative Certifications

- Automotive wireless charging: Complies with ISO 7637-2 for pulse immunity.

- Medical device charging: IEC 60601-1 medical safety certification.

IV. Supply Chain: Top-Tier Resources + Digital Management

1. Strategic Supplier Matrix

- Magnetic Materials: 0.15mm ultra-thin nanocrystalline shielding

- Coils: 99.9% pure copper wire with self-bonding technology

- CNC Machining: ±0.005mm aerospace-grade aluminum precision milling

2. Digital Collaboration

- ERP system for real-time inventory monitoring, material prep time reduced to 48 hours.

- Dual-supplier backup for critical components, ensuring zero supply chain disruption risk.

V. Customer Service: 24/7 Response + Full Transparency

1. Customized Service Process

1. Requirement Analysis Phase: Free competitor analysis report and technical feasibility assessment.

2. Development Phase: Weekly updates with 3D renderings/engineering prototype progress.

3. Mass Production Phase: Live factory monitoring for real-time status checks.

2. After-Sales Support System

- Lifetime Technical Support: Remote firmware upgrade services.

- Spare Parts Commitment: 5-year spare parts guarantee for discontinued products.

Why Global Clients Choose Huagon?